Part 2 - Expert Opinion

-

TITANE

The titanium project has its roots in a quest.

The story begins in 2003, when our technical partner asks us to work on comfort frames, capable of facing the cobblestones of the northern classics.

"We had already been working for a few years with a pro team. This time, they came to us with a special request: they wanted us to work on more comfortable and flexible frames to tackle the cobblestones of Paris-Roubaix and the Flanders classics," says Andrew, an engineer at the time.

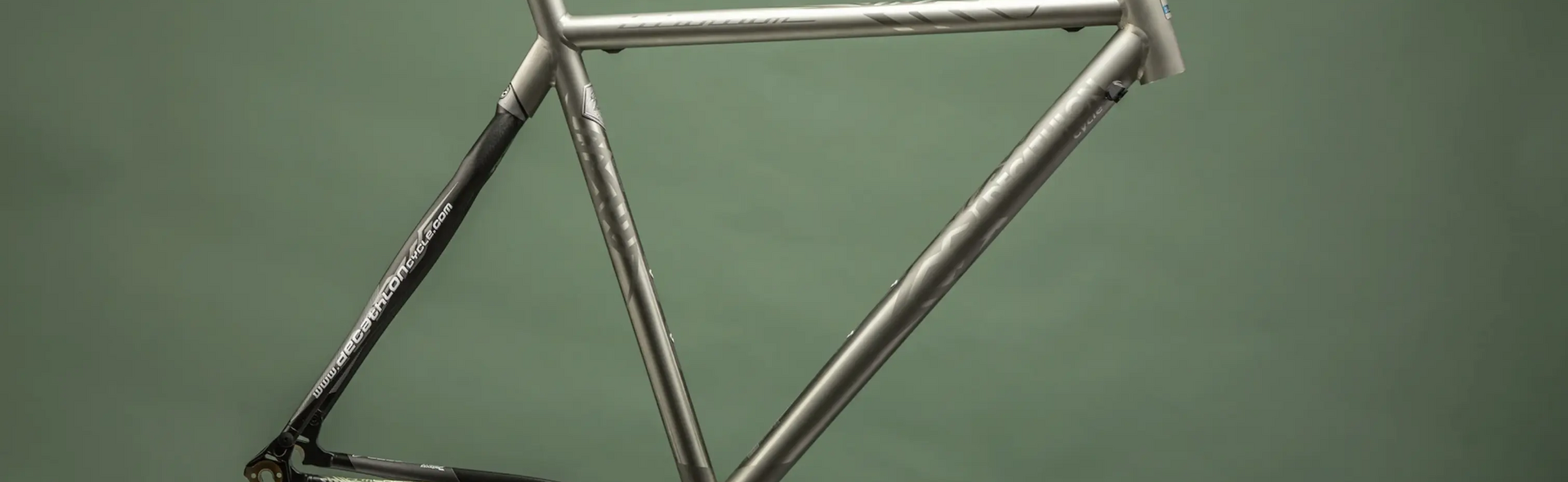

Titanium was ideal for this purpose. It's a comfortable, flexible material that has great advantages in terms of vibration absorption. "We developed a frame with a titanium architecture and a carbon rear triangle to add dynamism. It was a good compromise, the front part was soft, and the rear part was stiff. It was comfortable enough to get over the cobblestones or the somewhat destroyed roads of some races."

At the time, Alexandre Voisine was working on this specific project: "In terms of design, we tried to convey comfort through the image of titanium: we kept the color of titanium, that famous warm gray so particular, and played with masks and the contrast between brushed and sanded parts. The bikes were numbered, and small plates claimed the titanium by Dedacciai".

-

-

-

On this project Andrew Lorenzi is an engineer, Alexandre Voisine is a designer, and Dominique Broutin is the product manager. After a major benchmark of different suppliers, they chose to work with Dedacciai: it was already a reference in titanium, with very high quality materials, variable thicknesses to save weight, and tubes made in Italy... more than 15 years later, these three are still working for Decathlon and are still crazy about bikes. So when they return to Deda to present the rebirth of the titanium project, the team - still the same on the other side of the Alps - is more than enthusiastic. And it's the rebirth of a project, with the same partners, but with a very different use.

-

-

-

-

Before putting the pros on these bikes, the team started a big test phase: "We rode Paris-Roubaix twice, and it was extraordinary. We understood immediately and we adhered" remembers Andrew. And Alexandre adds "Riding on titanium is a different way of riding. It climbs really well, it's comfortable. It's a prestigious object, a raw material, unalterable and very durable. And that's part of the appeal of titanium, we know it will age well, and that it's timeless.

Today, the project is reborn and moves from paving stones to gravel. This time again, the comfort of the material is sought. And because victory is no longer the goal, the rear triangle is made of titanium and provides even more flexibility when cornering and on bumpy terrain. Titanium does not fear corrosion, this gravel will face the mud, the dirt, the rain. And a page opens up on endless wrinkles.

-

-

-